ABOUT US

Who we are

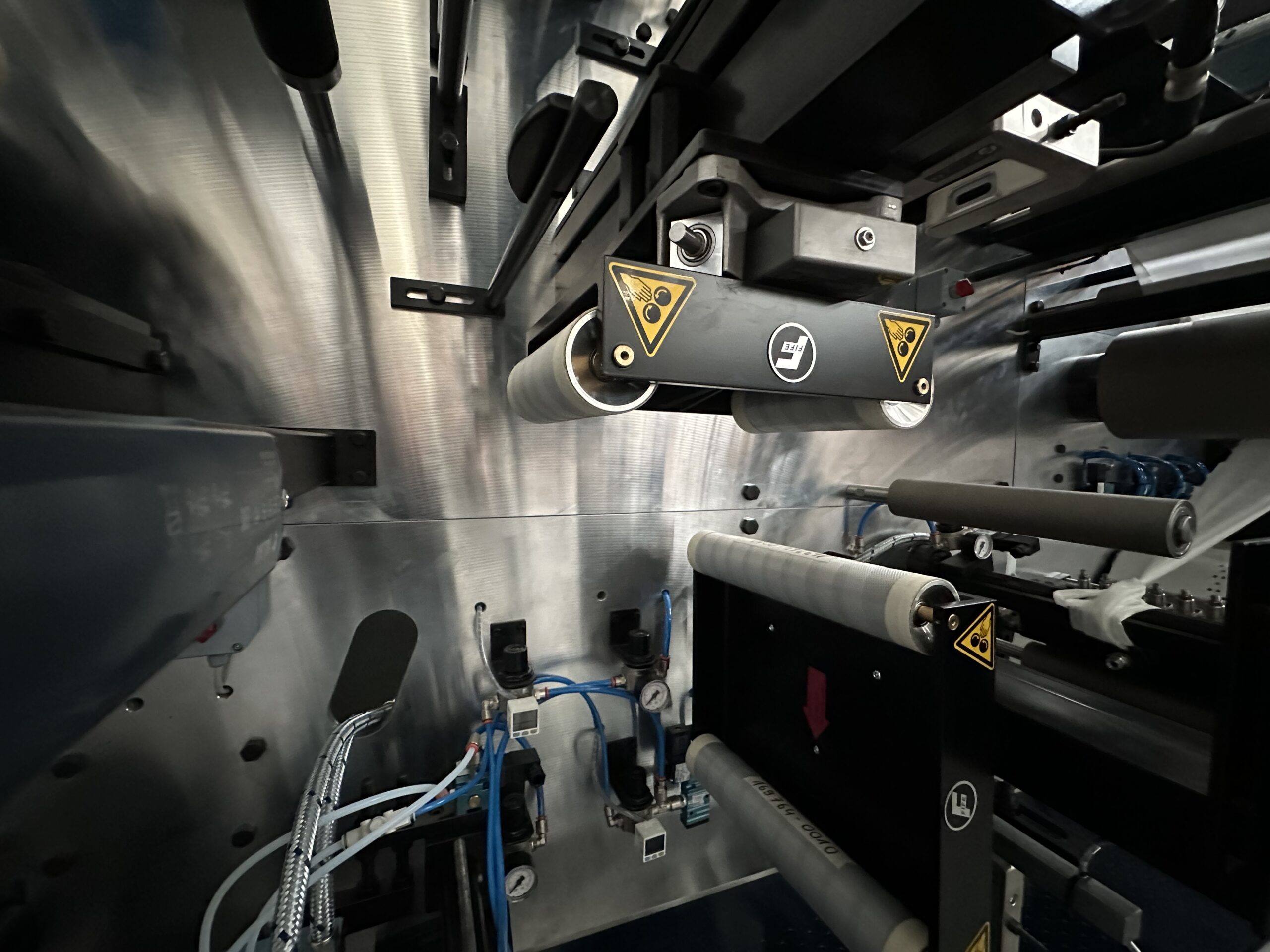

We are a company specialized in the production of technologically advanced machinery for the production of sanitary articles. M.D. Viola Macchine is a company with more than 40 years of experience in the sector, despite this, our philosophy has always been to remain a small family business, this gives us the possibility of having a direct dialogue with our customers so as to always be able to supply 100% Taylor made solutions on your requests. The company has a large mechanical workshop that allows us to produce almost all of the components used on our machines. We are also able to produce glue tanks, hot glue applicators, S.A.P dispensers and almost all of the accessory components that are necessary for a next generation machine. Furthermore, in case of urgent spare parts, we are always ready to respond to the customer’s needs by being able to produce the necessary pieces in a very short time.

Our Mission

THE CLIENT’S NEEDS ALWAYS COME FIRST

Every client is important to us. We are always ready to help, whether you are just starting production or you are already a well-established company. At M.D. Viola you always work directly with the owners, Davide and Marco Viola. We listen to our clients and create new products to meet the market changing needs. By speaking to us directly you know your project is our company’s top priority and your needs will be meet.

ADVANCED TECHNOLOGY REDUCES COSTS

We are continually improving and upgrading our technology to create money saving machines that decrease the cost of productions without impacting product quality and reliability. Our new machine’s feature improved SAP distribution and decreased hot melt used in diaper fabrication. This provides faster production speeds for Baby and Adult products with less maintenance. Our goal is to help our costumers decrease production costs while maintaining high quality.

ECO-FRIENDLY IMPROVEMENTS

We have substantially decreased the amount of energy needed for diaper fabrication. Our machines now use 30% less energy. – Productions costs are reduced because less electricity is needed – Eco-Friendly machinery requires fewer resources – Waste reduction

Since 1968

Our history

Year of establishment from Viola Giorgio of the Viola Giorgio Officine Meccaniche. At first the company started working with the Italian military department for the production highly precision component of military equipment and the production of valves for deep sea oil rigging.

Viola Giorgio Receives an award for work quality and Economic progress

Viola Giorgio is Nominated Cavaliere della repubblica italiana

Begging of production of pieces as a contractor for the hygiene industry

Development and Construction of the first Viola Baby Diaper Machine.

Development and construction of our first in house Hot-Melt Reservoirs and applicators

Development and Construction of the first Viola Adult Diaper Machine.

Viola Giorgio Receives an award For Exports Trades

Development and Construction of the first Viola Light Incontinence Machine.

First Patent Received

Development and Construction of the first Viola Automatic Packaging unit.

Construction of the Current Facility in Valle Salimbene

Rebranding From Viola Giorgio Officine Meccaniche to M.D. Viola Macchine S.R.L.

Construction of the first Full servo line

Development and Construction of the first Viola Adult Pants machine.

Development and Construction of the first Viola Baby Pants machine.

Purchase of new multi axis Machining center to increase productivity and parts complexity

Application For patent IT201800005900A1 our turning and repatching unit without limitations on machines speeds and patent IT201800006551A1 our new zero speed unwinder unit.

Starting the experimentation of design validation with vr google to increase machine ergonomics and ease of use

Addition of the new multi-axes machining centers to increase quality and production capabilities

New Logo For M.D. Viola Macchine